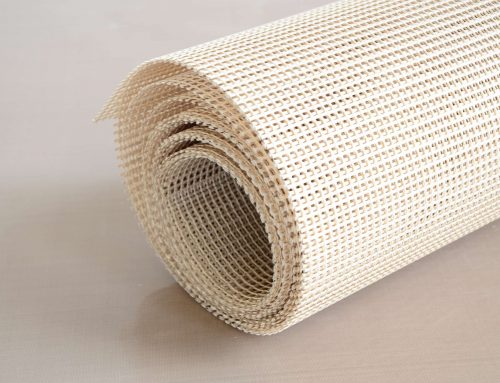

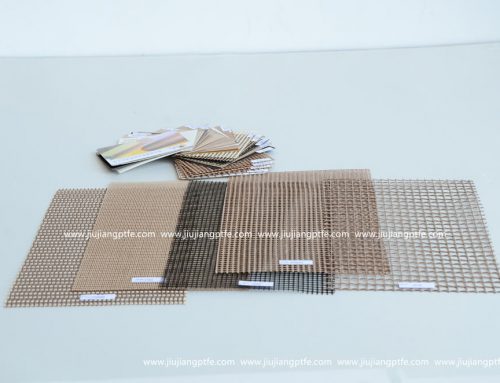

Teflon conveyor belt although has the properties of wear-resistant high temperature, but because of the load capacity and running fast, after a long run back and forth, the wear resistance of the conveyor belt will decline, Inevitably there will be wear and tear, glass fiber leakage problems encountered in these problems should be promptly repaired, otherwise the conveyor belt will be scrapped, affecting production schedule. So how to fix it?

Teflon conveyor belt sent wear common repair methods: Rubber patch up method, local rubber vulcanization method and rubber repair rubber covered repair method.

Adhesive patch method has the advantage of fast repair, as long as the subsidy at the polished cleaning adhesive after the cast glue, and then paste the patch even if the patch is good, you can boot run. The patch method is not very reliable, because after 60 ~ 90d operation, the film will fall off, And the use of the patch method, the conveyor belt can not run in a wet environment. Because the water vapor will accumulate in the gap between the bonding surface, rust wire rope, a long time will rust off the rope, or even the entire conveyor belt fracture, and the repair cost is relatively high.

Local vulcanized rubber vulcanization method is to use a small pair of local breakage vulcanized, sulfide by the size limit, repair speed is relatively slow, only 5m / h. So the repair method is not suitable for long-distance repair.

Rubber repair rubber cover method is to two-component polyurethane glue mixed together even after mixing, and then to fill the surface to be repaired, such as 5 to 6 hours after curing, curing will form an elastomer. The time required for general cure depends on the ambient temperature. After curing the appearance of the colloid and the conveyor belt has a good adhesive properties, bonding and sealing performance is very good, does not appear in the film after running off the problem, it will not operate in a wet environment rust off the rope, causing the belt breakage problems. After the repair method adopted, the abrasion resistance is very excellent, and the problem of local wear of the conveyor belt is effectively solved. At present, the repair method is the best effect, effectively extending the service life of the conveyor belt and avoiding the occurrence of broken belt.