Belt conveyor systems are widely used in the food industry for moving food products through different stages of production. They are an efficient and reliable way to transport food from one place to another, whether it’s from the production line to packaging or from the warehouse to the distribution center. However, not all belt conveyor systems are created equal, and choosing the right materials for your conveyor belt is crucial to the success of your business.

What is PTFE Mesh?

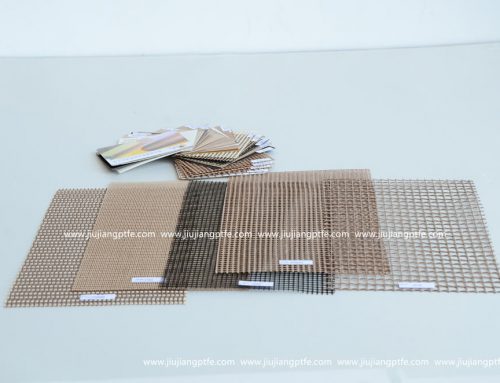

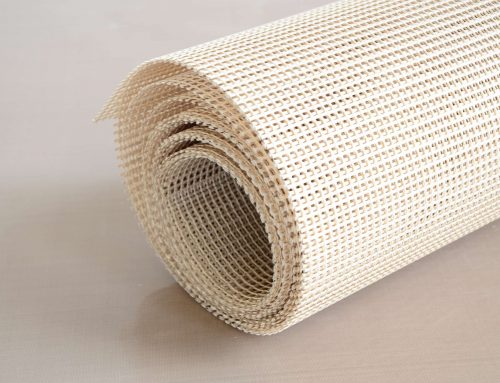

PTFE mesh is a type of fabric made from polytetrafluoroethylene (PTFE), a synthetic polymer that is commonly known as Teflon. PTFE mesh is woven from PTFE fibers, which are known for their high strength, durability, and resistance to chemicals, heat, and abrasion. PTFE mesh is commonly used in food processing applications due to its non-stick and non-toxic properties, which make it ideal for use in contact with food products.

Why Use PTFE Mesh in Belt Conveyor Food Applications?

- Non-Stick Surface

One of the main advantages of PTFE mesh is its non-stick surface, which prevents food products from sticking to the conveyor belt. This is particularly important in food processing applications where hygiene is critical, as food residues can harbor bacteria and other contaminants. PTFE mesh allows for easy cleaning and reduces the risk of cross-contamination, making it an ideal choice for food manufacturers.

- High Temperature Resistance

Another advantage of PTFE mesh is its high temperature resistance. PTFE mesh can withstand temperatures of up to 260°C (500°F) without losing its mechanical properties or releasing harmful fumes. This makes it ideal for use in baking and other high-temperature applications, where other materials may not be suitable.

- Chemical Resistance

PTFE mesh is highly resistant to chemicals, acids, and alkaline solutions, making it ideal for use in contact with food products. It can withstand exposure to a wide range of chemicals without degrading or releasing harmful substances into the food. This makes it an ideal material for use in harsh environments where other materials may be prone to corrosion or degradation.

- Durable and Long-Lasting

PTFE mesh is highly durable and long-lasting, making it a cost-effective choice for food manufacturers. It can withstand the rigors of daily use without breaking down or losing its mechanical properties. This means that PTFE mesh belts have a longer lifespan than other types of conveyor belts, which can save businesses money in the long run.

- FDA Approved

Finally, PTFE mesh is approved by the FDA for use in food processing applications. It is non-toxic, non-reactive, and does not contain any harmful substances that could contaminate food products. This makes it a safe and reliable choice for food manufacturers who need to meet strict food safety standards.

PTFE mesh is the best material for belt conveyor food applications due to its non-stick surface, high temperature resistance, chemical resistance, durability, and FDA approval. It is a safe and reliable choice for food manufacturers who need to transport food products through different stages of production. If you are in the food processing industry and need a reliable conveyor belt material, consider PTFE mesh for your business.