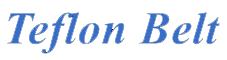

Teflon conveyor belt is made of glass fiber cloth and then coated with a special process Teflon emulsion made of a kind of high temperature conveyor belt. Will inevitably damage the conveyor belt if storage and use of improper maintenance. Then what matters to increase its service life should be paid attention to when storage and use and maintenance process?

When unloading Teflon conveyor belt to prevent the destruction of band-edge, preferably with a crane, and rigging with a rigging beam lifting, not barbaric handling.

To avoid the sun and rain, Teflon conveyor belt should be promptly warehousing, Warehouse must keep clean and dry, warehouse room temperature should be maintained at -15 ℃ ~ 40 ℃. Acid, alkali, oil and organic solvents are prohibited from direct contact, from the heat source device maintained at 1 meter away. Storage should be rolled into a roll placed, can not be folded, if the storage time is too long, should be turned once every quarter.

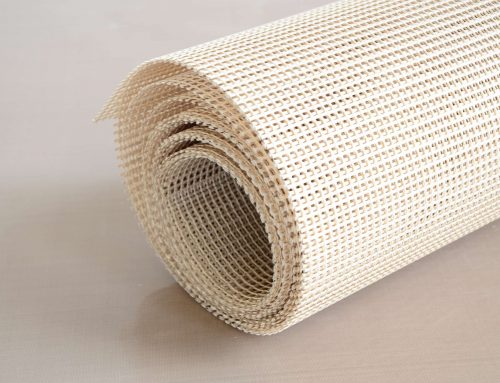

when used, which should be in accordance with the needs and specific conditions to choose the right type and specifications, different varieties, different specifications, strength, not the same number of Teflon conveyor belt can not be used in conjunction with a group.

In order to improve the reliability and maintain high effective strength, the Teflon conveyor belt joint can adopt the heat vulcanized rubber joint. The diameter of the conveying roller and the minimum pulley diameter of the conveyor belt shall meet the relevant requirements, and no meandering or creeping shall occur, to link the roller, stick flexible, tension should be appropriate.

If the conveyor needs to install the baffle and the installation of clean assembly, to prevent it from wear and tear, the installation should be very careful.

Due to foreign impurities will affect the belt running, resulting in deviation, uneven tension and even fracture, to avoid such problems must ensure good operation to have a high degree of cleanliness.

In the process of using the process if the early signs of destruction, to prevent adverse results, should be real-time search for the cause, the timely repair of damaged parts.