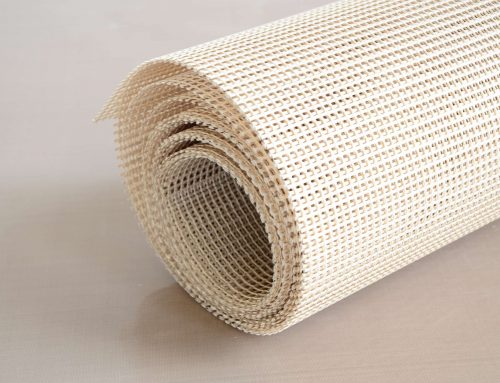

Teflon conveyor belt maintenance should pay attention to the nine points:

Teflon conveyor belt is best used lap high-temperature heat joint, the tensile strength of this kind of joint is the best

When the Teflon conveyor belt to transport materials, to avoid surface coverage by materials, resulting in rotation is not working, to prevent the leakage of materials in between the roller and tape.

If you find that Teflon conveyor belt local damage, the belt should be repaired in time to avoid the gap expansion.

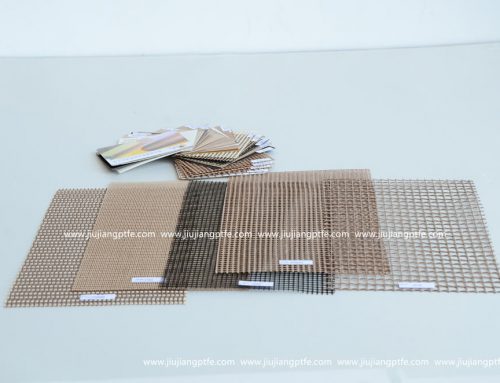

Conveyor belt selection should be reasonable, different varieties, different models, and different specifications conveyor belt can’t connected to use.

Do not bend the conveyor belt, to keep buffer heavy roller and side baffle rotation flexibility.

Baffle of drying equipment should be designed to be reasonable, safe and effective, and the edges of the Teflon mesh conveyor belt should not be worn.

To avoid the conveyor belt block by bearing roller, pillar or block material, to prevent break-breaking rip.

If Teflon conveyor belt deviation occurs, should take measures to correct timely.

Teflon conveyor belts need regular maintenance and maintenance, so as to increase its service life, long-term to maintain its coating adhesion and tensile strength.