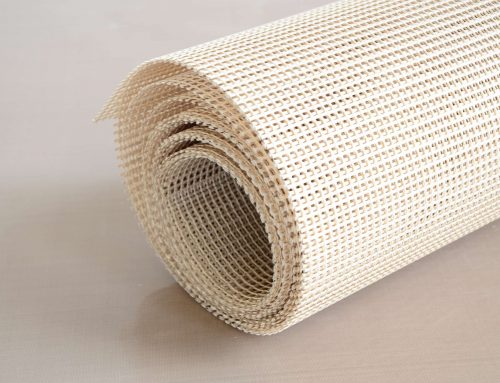

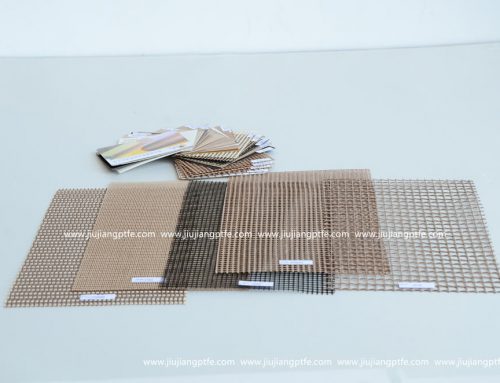

Teflon conveyor belt deviation is often seen in the process of using, it is easy to cause the production process can not be normal produced, Here are some common reasons and solutions of conveyor belt deviation.

1.Tension adjustment

Conveyor belt tension adjustment is a very important part of the dryer deviation adjustment. The two change drums at the top of the heavy hammer except should be perpendicular to the direction of the length of the conveyor belt, it also should be perpendicular to the vertical line of gravity, that is to ensure the axis of the centerline level. When tension is applied with screw or hydraulic cylinder, the two housings of the tensioner drum should be translated simultaneously, to ensure that the drum axis and the conveyor belt vertical direction perpendicular. The adjustment method of specific conveyor belt deviation is similar to the adjustment of drum.

2.The Influence of the transfer point blanking position for conveyor belt deviation

The transfer point blanking position has good impact for conveyor belt deviation, especially in the two conveyor belt machine in the horizontal plane of the projection into a greater impact when the vertical. Generally, the relative height of the two conveyor belts at the upper and lower loading points should be considered. The lower the relative height, the greater the horizontal velocity component of the material, the lateral impact of the lower belt conveyor is also greater, and materials are also difficult to center. So that the material in the conveyor belt cross section deflection, eventually leading to conveyor belt deviation. If the material is skewed to the right, the conveyor belt run to the left. In the design process should be as much as possible to increase the relative height of the two conveyor belts of machine. The width of the general guide groove should be about two-thirds of the conveyor belt width is better. In order to reduce or avoid the conveyor belt deviation can increase the block material, change the direction and location of the material falling.

3.Adjusting the deviation of the belt conveyor in the bidirectional running conveyor

The adjustment of the bidirectional running conveyor belt is much more difficult than one-way conveyor belt, in the specific adjustment should first adjust a direction, and then adjust the other direction. To carefully observe the conveyor belt movement and the relationship between the trend of deviation, adjust one by one. Emphasis should be placed on the adjustment of the drive roller and the change-over roller, and then adjust the roller and the material of the blanking point. At the same time should pay attention to the conveyor belt in the vulcanized joints should make the conveyor belt section of the force in the length direction uniform, In the use of chain traction, the force on both sides should as much as possible same.

4.Adjust the load roller group

The deviation of conveyor belt in the middle of the whole conveyor can be adjusted through adjust the deviation of the roller group position. At the time of manufacture, the mounting holes on both sides of the idler group are machined into elongated holes for adjustment. The specific method is the conveyor belt which side of the deviation, which side of the roller group conveyor belt forward direction forward, or the other side is moved backward. The conveyor belt upward deviation, than the roller group of the lower position should be moved to the left, the upper position of the roller group is moved to the right.

5.Install the aligning roller group

Aligning roller group has a variety of types such as the intermediate shaft type, four-link type, vertical roller type, The principle is to use the block or roller in the horizontal direction of the rotation or blocking the lateral thrust of the conveyor belt to the conveyor belt to achieve the purpose of automatic belt deviation. Generally, when the total length of the belt conveyor is short or when the belt conveyor is running in both directions, it is reasonable to adopt this method. The reason is that shorter belt conveyors are easier to run off and not easy to adjust. But the long size belt conveyor is best not to use this method, because the self-aligning roller group will have a certain impact on the conveyor belt service life.

6.Adjust the drive roller and the repositioning roller position

The adjustment of the driving roller and the rewinding roller is the important link of the conveyor belt deviation adjustment. Since a belt conveyor has at least two to five rollers, all drums must be mounted perpendicular to the center line of the belt conveyor in the length direction, if the deviation is too large deviation must occur. The adjustment method is similar to the adjustment of roller group. For the head drum, such as the conveyor belt to the right side of the drum deviation, the bearing on the right should be moved forward. Conveyor belt to the left side of the drum deviation, the bearing on the left side should be moved forward. Correspondingly, the left bearing block can also be moved backward or the right bearing block is moved backward. The adjustment of the tail roller is the opposite to the head roller. After repeated adjustment until the conveyor belt transferred to a more ideal location. It is advisable to accurately position it before adjusting the drive or steering rollers.

7.How to deal with the deviation of conveyor belt

Conveyor belt deviation is the most common fault in conveyor running. In order to solve this kind of failure, the most important is to pay attention to the installation of dimensional accuracy and routine maintenance. There are many reasons for deviation, so need to be treated differently according to different reasons.

If you want get to know more about Teflon conveyor belt or you want to purchase Teflon conveyor belt, please don’t hesitate to contact us [email protected]. Our people will answer you as soon as possible. Thank you!