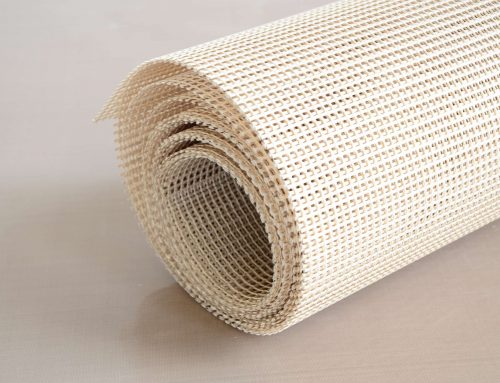

There are many kinds of Teflon conveyor belt, such as Teflon mesh conveyor belt, Teflon coated fiberglass belt, Teflon seamless belt, Teflon seam belt, Teflon welding machine belt, etc.

Conveyor is a kind of material handling machinery that can continuously convey materials on certain lines, it can be used to transport all kinds of light materials, with a large amount of transportation, low operating costs, a wide range use of features. Teflon conveyor belt is usually used on the conveyor, then how to install and commission the Teflon conveyor belt?

With the transmission part of the unit, the general shipping choice is packing shipping, we must pay attention to avoid bump when unpacking, the Teflon conveyor belt should be checked before installation, if any dirt, the belt should be cleaned first. When lifting, we should be careful to avoid deformation of the parts.

After the transfer tower and bunker can be installed. Normally, Teflon conveyor belt do not need embedded when installing, fix the device with expansion bolts first, no need special treatment on the ground, because the device foot height can be adjusted. Then draw the center line of each device on the ground according to the size marked on the general drawing, this center line must be consistent with the center line of the relevant equipment, the installation must follow up the line, tighten the feet with expansion bolts. To Install according to geological parameters and drawing requirements, and ensure that all moving parts are flexible. To adjust the height, straightness and level of each conveying surface according to the drawings. Then laying electrical slot (tube), install distribution cabinets and wiring etc. To adjust the appropriate degree of the tensioning device in accordance with the requirements.

The commissioning will be carried out after installation in order to meet the requirements, the individual equipment can be a manual test and combined with commissioning to see if it can meet the operational requirements. Before commissioning, the gear units and moving parts should be filled with the correct lubricating oil. In order to have good performance of the equipment and to achieve the designed function and status, the electrical part of the commissioning Teflon conveyor belt includes the commissioning of the electrical wire connections and function.

During the storage and transportation of the conveyor which installed Teflon conveyor belt in summer, take precautions and avoid direct contact of parts with rain.

Shenzhen Core-Tex is specialized in Teflon coated fiberglass products, with many years experience in Teflon products R & D design and application. If you have any questions in the use of Teflon conveyor belt, please feel free to contact us [email protected], our engineers will answer your questions in time.