The main popular color of high-temperature cloth for sealing machine is brown or deep-brown. It is made of high-quality glass fiber cloth and is made by using ultra-wide dipping machine repeatedly and repeatedly coated with high-quality Teflon resin. The thickness is generally 0.08. Mm, 0.11mm, 0.13mm, the weave type is mainly plain.

It generally has the following characteristics and advantages:

1, temperature resistance. It is used for low temperature -196℃, high temperature 360℃, weather resistance and anti-aging.

2, non-adhesive: It is not easy to adhere to any substance. It is easy to clean all kinds of oil stains, stains or other attachments attached to its surface; almost all adhesive substances such as paste, resin, paint, etc. can be easily removed;

3, resistant to chemical corrosion,it can withstand the corrosion of strong acid, alkali, aqua regia and various organic solvents.

4, low friction coefficient (0.05-0.1), is the best choice for oil-free self-lubrication.

5, with high insulation performance (different dielectric constant: 2.6, tangent below 0.0025), UV protection, anti-static.

6, good dimensional stability (extension coefficient less than 5 ‰), high strength. Has good mechanical properties.

7, drug resistance, non-toxic. Almost all drug items are available.

8, fire retardant.

How to use the high temperature cloth tape of the sealing machine:

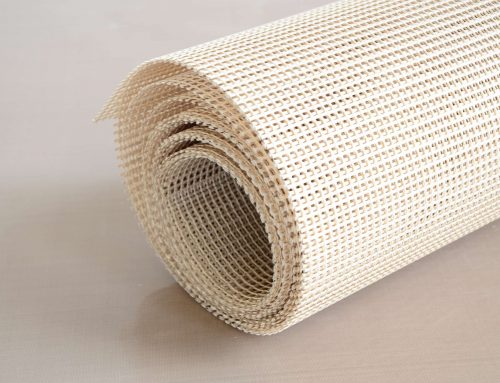

PTFE tape special (iron) From high-temperature tape is made of imported glass fiber woven various base fabrics, and then coated with imported PTFE. It is processed by special process. It is a new high-performance, multi-purpose composite material. It is widely used in paper, food, environmental protection, printing and dyeing, clothing, chemical, glass, medicine, electronics, insulation, grinding wheel slicing, machinery and other fields.

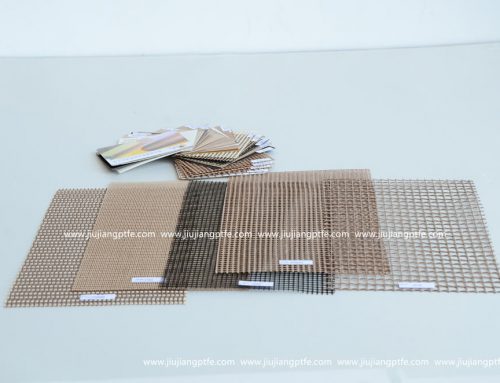

Main features of Teflon tape :

1, for low temperature -196℃, high temperature 300℃, with weather resistance, anti-aging. After practical application, such as continuous temperature for 250 days at 250℃, not only the strength will not become low, but also the weight is not reduced; at 350℃.After being placed at high temperature for 120 hours, the weight is only reduced by about 0.6%; under the condition of -180℃ ultra-low temperature, the original softness can be maintained.

2, non-adhesive: the surface is smooth, not easy to adhere to any substance. It is easy to clean all kinds of oil stains, stains or other attachments attached to its surface; almost all adhesive substances such as paste, resin, paint, etc. can be easily removed.

3, resistant to chemical corrosion,it can withstand the corrosion of strong acid, alkali, aqua regia and various organic solvents.

4, drug resistance, non-toxic. Almost all drug items are available.

5, with high insulation performance (different dielectric constant: 2.6, tangent below 0.0025), UV protection, anti-static.

6, fire retardant.

7, easy to use, long service life. 9. It is easy to tear off, and it is sticky at the same time, and it does not leave glue after tearing off. This is something that many manufacturers can’t do!

The scope of application of tape:

1. It is a heat-sealed pressure-bonding part for packaging food, rice pockets, medicines, etc.

2. Used as a heat seal for plastic film.

3. It is used to package the surface of the precision roller for dyeing and resin processing.

4. Used to package the surface of the roll of the adhesive, applicator coating machine.

5. It is used to wrap the friction surface of the hopper and guide rail.

6. Used to package non-adhesive and areas that need to maintain smoothness.

7. Used as a lining for equipment accessories.

8. Used as insulation gasket, insulation over-lock for insulation parts and other insulation over-locks.