The University of Surrey in the UK (Universityofsurrey) has reportedly teamed up with Hopkins University (hopkinsuniversity) to produce a new material that could be used in future car manufacturing. The new material is resistant to intense vibrations and has excellent noise suppression effects (muffler, sounddampening).

The University of Surrey has reportedly teamed up with Hopkins University to produce a new type of material that might make its way into future automobile manufacturing. The new material in question can withstand vigorous vibrations and has superior sound dampening qualities.

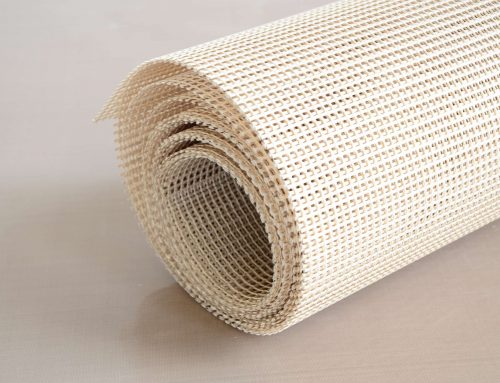

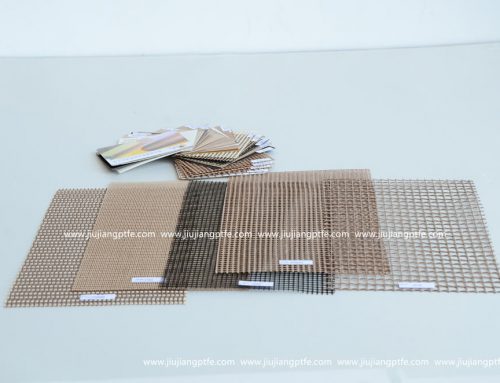

The researchers used multi-layer 3D weaving Technology Textile structural composites (3Dwoventechnicaltextilecomposites) as fiber materials, the arrangement of each layer of materials makes the intermediate textile structure layer active, while the external layers of materials remain rigid, Thus, in the case of high rigidity can also obtain a good damping effect.

The researchers used layers of 3D woven technical textile composites as fiber materials. This arrangement of layers will enable the middle layers of the textile to move while the outside layers stay rigid. This is how the new material maintains high rigidity while having dampening abilities.

The properties of such materials are rare in conventional materials because the increased rigidity means that the mobility of the internal particulate matter decreases, resulting in a weakening of the damping effect. Conversely, while ensuring damping ability, rigidity will weaken. This is why metals having high rigidity with a low dampening ability and a material like foam being less rigid but having high dampening ability.

There is no doubt that the researchers ‘ new inventions are impressive and will have a big impact on the manufacture of many products, especially those that require both these properties.

Think about replacing the standard body panel materials like aluminum and steel with this new material. Passenger cabin among cars will become more silent when vehicle is moving. Today, automobile enterprises have adopted a large number of soundproof materials to keep sound and vibrations away from getting into the passenger cabin.

However, this requires sacrificing the overall vehicle performance and fuel economy, and the introduction of soundproof materials will not only affect the performance of the vehicle, but also reduce the space inside the car. However, the use of 3D woven textile structural composites, not only to achieve the vehicle weight reduction target, but also to enhance the space inside the car. In addition, the material is promising, thanks mainly to its high temperature resistance.

As described in the research paper, “In addition to damping and 13 mechanical properties, this 3DW lattice materials also demonstrates customized fluidic permeability, thermal transport and high temperature resistance, which can provide a variety of functions for future research. ”