Belt Conveyor Food: Why PTFE Mesh is the Best Material for Your Business

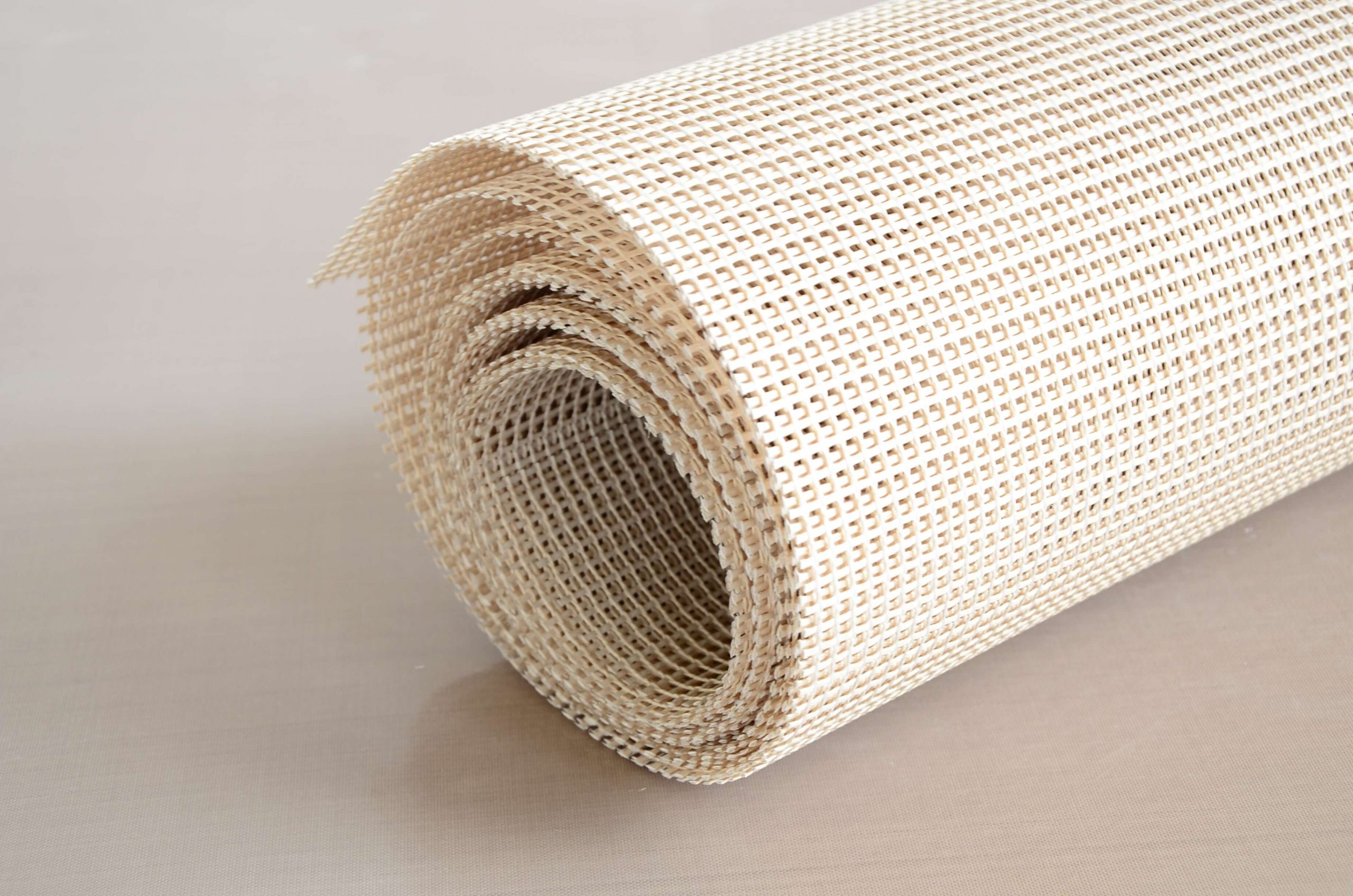

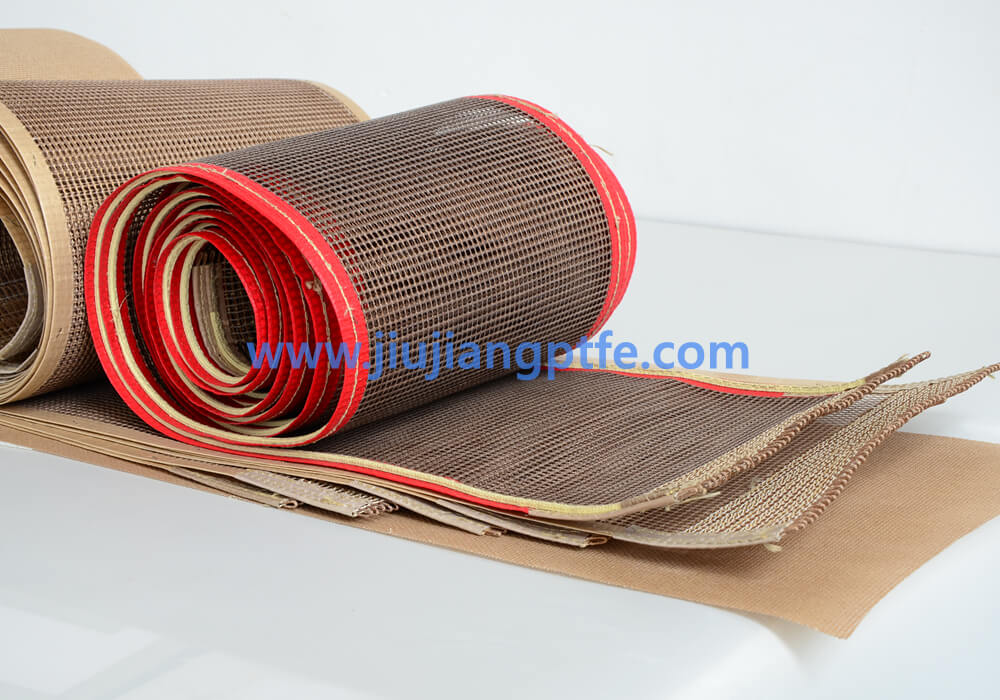

Belt conveyor systems are widely used in the food industry for moving food products through different stages of production. They are an efficient and reliable way to transport food from one place to another, whether it's from the production line [...]